Testing is the process of evaluating a product, material, system, or service to ensure it meets specific requirements, standards, or expectations. It helps identify defects, validate quality, ensure compliance with regulations, and confirm suitability for intended use.

1. Quality Testing Solutions

These are testing methods and services aimed at ensuring product or service quality. Key aspects include:

Functionality Testing: Ensures the product works as expected.

Performance Testing: Checks speed, responsiveness, and stability.

Reliability Testing: Evaluates how long the product performs under specific conditions.

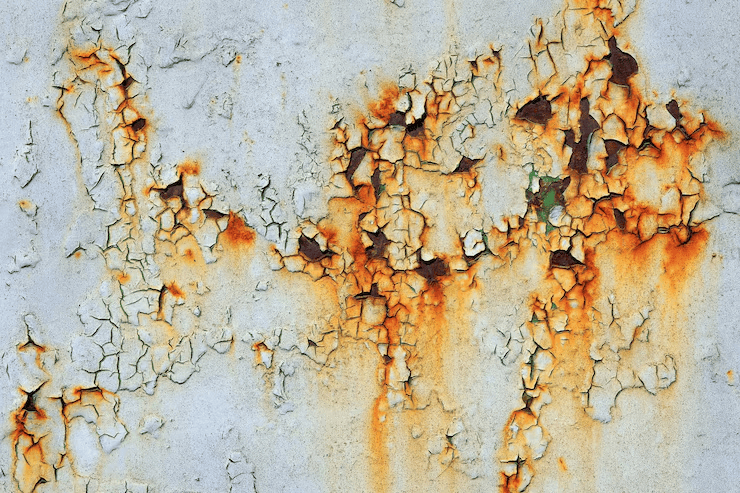

Durability Testing: Ensures the product withstands wear and tear.

Software QA Testing: In IT, this ensures bug-free and efficient applications.

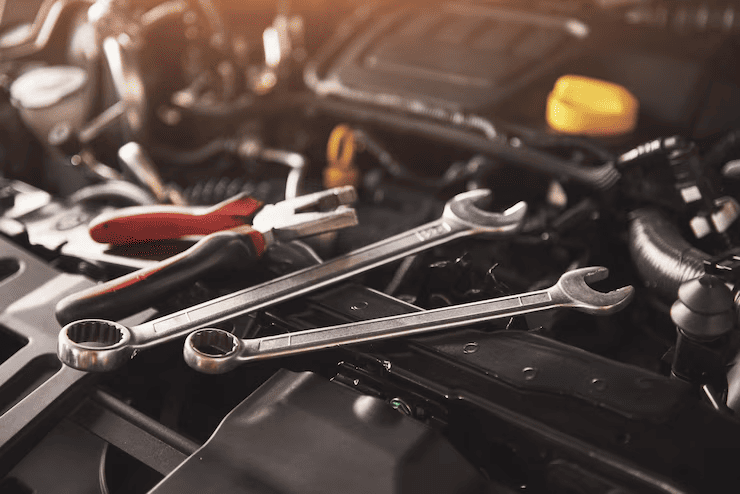

Industries: Manufacturing, software, automotive, electronics.

2. Material Testing

Material testing checks the physical and mechanical properties of materials to verify strength, composition, and usability.

Used in: Construction, aerospace, automotive, civil engineering.

3. Compliance Testing

Also called Conformance Testing, it ensures that a product or system adheres to relevant standards, laws, and regulations.

ISO Standards Compliance (e.g., ISO 9001, ISO 27001)

Electrical Safety Compliance (e.g., CE marking)

Environmental Compliance (e.g., RoHS, REACH)

FDA/Medical Device Testing

Industries: Pharmaceuticals, electronics, food processing, consumer goods.

4. Industrial Testing Services

Comprehensive testing provided to industrial sectors to ensure safety, reliability, and quality of machinery, components, and systems.

Non-Destructive Testing (NDT): Like X-rays, Ultrasonic, Magnetic Particle Testing

Vibration and Shock Testing

Load Testing

Pressure Vessel Testing

Welding Inspection

Industries: Oil & gas, manufacturing, power plants, heavy engineering.