What is Required NDT-LT?

Non-Destructive Testing – Leak Testing (LT) that is essential or mandated in specific industries or applications to ensure the integrity, safety, and reliability of components, systems, or structures that must remain leak-proof under service conditions.

✅ What is NDT-LT?

Leak Testing (LT) is one of the key Non-Destructive Testing (NDT) methods used to detect and locate leaks or verify the leak-tightness of systems without causing any damage. It is primarily used in pressure vessels, pipelines, storage tanks, heat exchangers, and sealed components.

🔍 What is Required NDT-LT?

“Required NDT-LT” means that Leak Testing is mandatory:

- Due to regulatory compliance (e.g., ASME, ISO, ASTM codes),

- Because of critical service conditions (e.g., gas pipelines, nuclear systems),

- Or as a customer/contractual specification.

It ensures:

- No loss of hazardous or valuable material (gas, oil, refrigerant, etc.),

- Environmental and personnel safety,

- Operational efficiency and equipment life extension.

🧪 Techniques in Required NDT-LT:

Leak Testing methods used depend on sensitivity, size, location, and test medium. Common LT methods include:

| Method | Use Case |

|---|---|

| Bubble Soap Testing | Quick check for visible leaks in low-pressure systems |

| Pressure Drop Testing | Measures pressure decay in sealed systems |

| Helium Mass Spectrometry | High sensitivity, used in aerospace and vacuum tech |

| Vacuum Box Testing | Used on welded joints in tanks or vessels |

| Halogen Diode Testing | Detects halogen-based gas leaks (like refrigerants) |

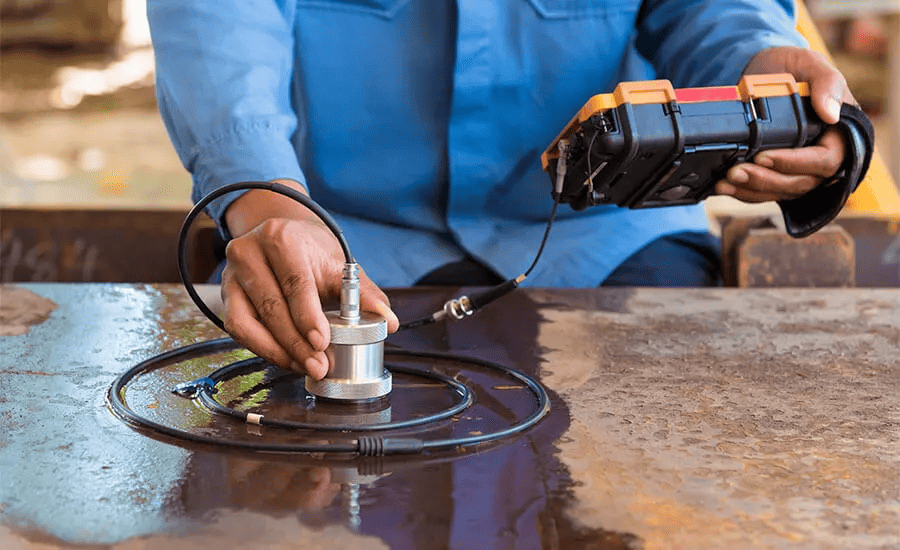

| Ultrasonic Leak Detection | Detects high-frequency leak sounds in pipelines |

🏭 Where is Required NDT-LT Used?

- Oil & Gas Industry – Pipelines, storage tanks

- Aerospace & Aviation – Fuel and hydraulic systems

- Pharmaceutical & Food – Sterile sealed systems

- Nuclear Power Plants – Reactor coolant systems

- Automotive – Fuel and air-conditioning systems

- Refrigeration & HVAC – Leak-proof performance

📅 When is Required NDT-LT Performed?

- During initial manufacturing and fabrication

- As part of routine maintenance

- After repairs or retrofits

- Prior to commissioning and certification

- For quality audits or regulatory inspections

🧰 How is Required NDT-LT Conducted?

- Preparation – System cleaned, isolated, and filled with test medium.

- Method Selection – Based on sensitivity and application.

- Leak Detection – Visual, acoustic, or sensor-based monitoring.

- Result Evaluation – Compare to acceptable leak rate standards.

- Documentation – Reports, images, and approval for compliance.

📄 Example Case Study: Helium Leak Testing in Nuclear Reactor

Client: Nuclear plant manufacturer

Need: Ensure no helium leakage from coolant loops

Method: Mass Spectrometer Helium Leak Test

Result: Detected microleak at welded joint, repaired before critical failure

Outcome: Prevented costly downtime and radiation risk

📘 White Paper Insight

A white paper on Required NDT-LT would detail:

- Comparative study of different LT methods

- Sensitivity charts

- Industry best practices

- Calibration of LT equipment

- Case studies and failure analysis

Who is Required NDT-LT?

NDT-LT (Leak Testing as a Non-Destructive Testing method) is mandatorily required by individuals, companies, and sectors where leakage of fluids, gases, or hazardous substances could pose safety risks, environmental harm, regulatory non-compliance, or financial losses.

🏭 Industries & Professionals Who Require NDT-LT:

| Entity | Why They Need NDT-LT |

|---|---|

| Oil & Gas Companies | To detect leaks in pipelines, storage tanks, offshore rigs |

| Aerospace Manufacturers | To ensure aircraft fuel and hydraulic systems are leak-proof |

| Power Plants (Nuclear & Thermal) | To verify reactor coolant loops, steam lines, and containment vessels |

| Pharmaceutical & Food Processors | For sterile, contamination-free sealed systems |

| HVAC & Refrigeration Manufacturers | To check refrigerant lines and compressor seals |

| Automotive Industry | To test engine parts, brake lines, air conditioning systems |

| Shipbuilding and Marine Industry | For watertight compartment and pipeline integrity |

| Welders & Fabricators | To verify weld seams on pressure vessels and tanks |

| QA/QC Inspectors | For third-party or internal certification and audits |

| Maintenance Engineers | For periodic leak checks in running systems |

📋 Regulatory Bodies Requiring NDT-LT Compliance:

| Organization | Requirement |

|---|---|

| ASME (Boiler & Pressure Vessel Code) | Leak testing required for pressure-rated components |

| ISO Standards (e.g., ISO 9712) | Specifies personnel certification and LT methods |

| API (American Petroleum Institute) | Mandates LT for pipelines, storage, and process units |

| FDA / GMP Guidelines | Leak integrity of pharma/food packaging |

| NRC (Nuclear Regulatory Commission) | LT as part of nuclear safety protocols |

| DOT (Department of Transportation) | For transport tanks and pipelines |

| CE Marking (Europe) | Requires LT for pressure equipment directive (PED) compliance |

🧑🔧 Who Performs Required NDT-LT?

| Role | Responsibility |

|---|---|

| Certified NDT Level I/II/III Personnel (ASNT/ISO 9712) | Execute, interpret, and supervise leak testing |

| QA/QC Engineers | Review and approve LT results for compliance |

| Third-party Inspection Agencies | Conduct independent validation of leak integrity |

| Maintenance Technicians | Use portable LT methods for on-site checks |

| Design & Process Engineers | Specify leak testing requirements in design phase |

| Regulatory Auditors | Review LT procedures and documentation for compliance audits |

🔧 Summary

Who is Required NDT-LT?

Anyone responsible for designing, manufacturing, operating, inspecting, or certifying sealed systems or pressure-retaining components across industries like oil & gas, power, aviation, pharma, HVAC, automotive, etc. They are either legally required, contractually obligated, or safety-driven to perform leak testing as part of standard NDT practices.

When is Required NDT-LT?

NDT-LT (Leak Testing) is performed at critical stages of a product or system’s lifecycle where leak integrity is essential for safety, compliance, or performance. The timing of leak testing depends on industry norms, legal mandates, and operational requirements.

✅ Key Moments When NDT-LT is Required:

| Stage | Description | Purpose |

|---|---|---|

| 1. During Design & Prototyping | Leak testing is specified in design documents and early prototypes are tested | Ensures product design meets leak-proof standards before mass production |

| 2. After Fabrication or Welding | Performed immediately after welding joints, piping, or tanks | Verifies structural integrity and weld soundness |

| 3. Before Commissioning | Conducted before starting the equipment or system for the first time | Ensures leak-tight operation under working pressure |

| 4. Periodic Maintenance & Inspections | At scheduled intervals (monthly, annually, etc.) | Prevents undetected leaks that could lead to downtime or hazards |

| 5. After Repairs or Modifications | Mandatory post-repair testing of any modified pressure system | Validates restoration of leak integrity |

| 6. Regulatory or Third-Party Audit | As part of compliance inspections or certifications | Satisfies government, customer, or third-party requirements |

| 7. Before Shipment or Delivery | Leak testing of sealed products or components before dispatch | Ensures zero defects and protects brand reputation |

| 8. Incident Investigation | After failure, explosion, or environmental event | Leak testing helps identify root cause of failure or leak source |

📆 Industry-Specific Timelines

| Industry | When Leak Testing is Required |

|---|---|

| Oil & Gas | After pipe laying, valve installation, and before startup |

| Pharma/Food | During batch processing validation and packaging QA |

| Automotive | After engine assembly, before final inspection |

| HVAC/Refrigeration | During final QC and post-repair service |

| Nuclear/Power Plants | At every planned outage, and pre-startup of safety systems |

⏱ Legal & Standards-Driven Timing

Leak Testing is required by law or codes at defined intervals or process stages:

- ASME Section V: Mandates leak testing for pressure vessels post-fabrication

- ISO 14644 / 14698: Cleanroom component testing intervals

- FDA/CGMP: Packaging integrity testing before product release

- PED (EU Directive): Leak test before CE marking

🔁 Summary

Required NDT-LT is performed whenever leak integrity is critical — before use, after construction or repair, periodically for maintenance, or when mandated by law or industry codes.

Where is Required NDT-LT?

NDT-LT (Leak Testing) is performed in locations and environments where systems, equipment, or components must remain sealed under pressure or vacuum — to prevent leakage of gases, liquids, or hazardous materials. These locations span a wide range of industries, from factories and production floors to field installations and critical infrastructure.

🏭 Common Locations Where NDT-LT is Required:

| Location Type | Examples of Leak Testing Application |

|---|---|

| Manufacturing Plants | Testing valves, tanks, compressors, pipe assemblies |

| Refineries & Petrochemical Plants | On-site leak detection in pipelines, reactors, and exchangers |

| Power Generation Facilities | Testing condensers, steam lines, reactor systems |

| Aerospace Assembly Hubs | Leak checking hydraulic, fuel, and oxygen systems in aircraft |

| Automotive Production Lines | Leak testing engine cooling systems, fuel tanks, brake lines |

| Pharmaceutical & Biotech Labs | Ensuring packaging integrity, cleanroom barrier seals |

| HVAC Installation Sites | Leak testing refrigerant lines, duct systems, and AC units |

| Nuclear Plants | Testing coolant loops, containment vessels, safety systems |

| Food & Beverage Factories | Packaging leak testing (vacuum packs, PET bottles) |

| Shipyards & Marine Platforms | Leak integrity in ballast tanks, fuel systems, and pressure hulls |

| Construction Sites (Oil & Gas Pipelines) | Field-based hydrostatic or pneumatic leak tests of pipeline joints |

🗺️ Geographical Regions with Mandatory NDT-LT Requirements:

| Region | Typical Requirement Examples |

|---|---|

| India | BIS/IBR/ISO standards for pressure vessels, pharma packaging |

| USA | ASME Section V, DOT regulations, FDA for medical/pharma |

| Europe | PED (Pressure Equipment Directive), CE marking, ISO standards |

| Middle East (e.g., UAE, KSA) | Oil & gas field pipeline integrity, refinery safety |

| Japan | High-standard leak testing for nuclear and automotive industries |

| China | Leak testing for consumer electronics, industrial manufacturing |

| South Korea | Electronics, shipbuilding, and automotive leak testing protocols |

🏗 Where on the Component or System?

| Component | Leak Test Focus |

|---|---|

| Welded Joints | Common failure point in tanks and pipelines |

| Valves & Flanges | Tested for sealing under pressure |

| Heat Exchangers | Leak tests for tube-to-tube sheet joints |

| Pumps & Compressors | Seal testing under operating conditions |

| Sealed Packaging | Integrity of blister packs, sachets, or vacuum packs |

| Fuel Systems | Automotive and aerospace fuel delivery systems |

✅ Summary

Required NDT-LT is performed wherever sealing, containment, or pressure integrity is critical — whether on a factory floor, a power plant, an oilfield, a packaging line, or in an aircraft hangar. Its purpose: to prevent leaks, ensure safety, protect the environment, and maintain performance.

How is Required NDT-LT?

NDT-LT (Leak Testing) is carried out using specific procedures, tools, and standards to detect, locate, and measure leaks in systems without damaging them. The method chosen depends on sensitivity needs, component type, medium being contained (gas or liquid), and regulatory requirements.

🛠️ Step-by-Step Process of Required NDT-LT

| Step | Description |

|---|---|

| 1. Define Test Objective | What are you testing? What type of leak is unacceptable? |

| 2. Select LT Method | Based on required sensitivity, medium, system pressure, and accessibility |

| 3. Prepare the Component | Clean surface, seal system, isolate valves, ensure dryness if required |

| 4. Apply Test Medium | Pressurize with air, nitrogen, helium, water, or create a vacuum |

| 5. Perform the Test | Using instruments or visual observation depending on method |

| 6. Evaluate the Results | Compare to acceptable leak rates defined in standards or specs |

| 7. Document the Test | Record method, conditions, results, inspector signature, and pass/fail status |

⚙️ Common Required Leak Testing Methods

| Method | Description | Use Case |

|---|---|---|

| Bubble Soap Test | Apply soap solution and watch for bubbles | Quick checks, welds, fittings |

| Pressure Drop Test | Monitor pressure decay over time | Pipes, sealed systems |

| Vacuum Box Test | Spray soap, use vacuum chamber to detect bubbles | Weld seams on tanks |

| Helium Mass Spectrometer Test | Detect helium escaping from leaks using mass spectrometer | High-sensitivity tests (e.g., nuclear, aerospace) |

| Ultrasonic Leak Detection | Use microphone to detect high-frequency sound of leak | Noisy environments, inaccessible areas |

| Tracer Gas Method (e.g., Halogen) | Sniffers detect escaping tracer gases (e.g., refrigerants) | HVAC, refrigeration systems |

🧰 Tools & Equipment Used in Required NDT-LT

- Soap solution or bubble spray

- Digital pressure gauges and data loggers

- Vacuum pump and vacuum box kits

- Helium leak detectors or mass spectrometers

- Ultrasonic detectors

- Sniffer probes for halogen or hydrogen-based gases

- Test chambers for sealed product testing

- Leak calibrators for sensitivity checks

📏 Standards Followed

| Standard | Application |

|---|---|

| ASME Section V Article 10 | Leak testing for pressure vessels and boilers |

| ISO 20485 | General NDT guidelines for leak testing |

| ASTM E515 / E499 | Helium and pressure testing protocols |

| API 650/653 | Storage tank leak test methods |

| FDA/CGMP Guidelines | Pharma and packaging integrity |

| EN 1779 / EN 13184 | Sensitivity classification and tracer gas methods |

🧪 Leak Rate Measurement

Leak rate is often expressed as:

bashCopyEditatm·cc/sec, mbar·L/sec, or Pa·m³/sec

Depending on your application, acceptable leak limits may range from:

- 10⁻⁵ atm·cc/sec (nuclear or aerospace) to

- Visible bubbles (in simple soap tests for HVAC or piping)

✅ Summary

Required NDT-LT is carried out through standardized, calibrated, and documented procedures to verify that no unacceptable leakage occurs in critical systems. The method depends on risk level, industry, and regulatory compliance.

Case Study on NDT-LT?

Preventing Catastrophic Gas Leak in a Petrochemical Plant Using Helium Mass Spectrometer Testing

🏭 Background

Client: A leading petrochemical company in Gujarat, India

System: High-pressure heat exchanger system in a gas separation unit

Industry: Oil & Gas

Standard Followed: ASME Section V, ISO 20485

Testing Method: Helium Mass Spectrometer Leak Detection (Vacuum mode)

⚠️ Problem Statement

During pre-commissioning inspection, routine pressure decay testing indicated a potential micro leak in one of the shell-and-tube heat exchangers. However, the leak location could not be pinpointed using soap bubble or pressure hold methods due to:

- Extremely small leak rate

- High system complexity

- Risk of contaminant ingress during standard methods

A non-invasive, highly sensitive testing method was urgently needed to locate and measure the leak without compromising the system integrity.

🔧 Solution Implemented

Selected Method: Helium Mass Spectrometer Testing (Vacuum Method)

✅ Steps Taken:

- Test Preparation:

- System was sealed and connected to a helium mass spectrometer.

- A vacuum was drawn inside the shell side of the exchanger.

- External surfaces were sprayed with helium tracer gas.

- Leak Detection:

- The spectrometer detected helium ions entering through the leak site.

- Leak was precisely located near a tube-to-tube sheet weld joint.

- Leak Quantification:

- Leak rate measured at 2.8 x 10⁻⁶ atm·cc/sec, exceeding the plant’s allowable limit of 1.0 x 10⁻⁶ atm·cc/sec.

- Corrective Action:

- The defective weld was reworked by certified TIG welders.

- Post-repair testing confirmed zero leak within allowable limits.

📈 Results

| Metric | Before | After |

|---|---|---|

| Leak Detection | Inconclusive (bubble/pressure methods) | Precise (tube-to-tube sheet) |

| Leak Rate | 2.8 x 10⁻⁶ atm·cc/sec | ≤ 1.0 x 10⁻⁷ atm·cc/sec |

| Time to Locate Leak | >2 days | <3 hours |

| Downtime Risk | High | Eliminated |

| Safety Risk | Critical | Mitigated |

🧠 Key Learnings

- Traditional methods may not detect micro-leaks in complex systems.

- Helium Mass Spectrometer Testing offers unparalleled sensitivity and precision.

- Early detection using advanced NDT-LT methods prevents financial loss and environmental hazards.

- Well-trained, certified NDT technicians were crucial to the success of the test.

📝 Conclusion

This case clearly illustrates how Required NDT-LT using high-sensitivity methods like helium leak testing is essential in high-risk, high-value industrial systems. Choosing the right method, timely intervention, and skilled execution can avoid accidents, save costs, and ensure regulatory compliance.

White paper on NDT-LT?

Title:

Ensuring Pressure Integrity and Environmental Safety through Required NDT-LT: A Comprehensive Guide to Leak Testing

🔍 Abstract

This white paper presents an in-depth overview of Required Non-Destructive Testing – Leak Testing (NDT-LT), a critical quality assurance method across pressure-sensitive industries. It explores testing principles, methodologies, industry applications, standards, challenges, and future trends, supporting decision-makers, engineers, and regulators in maintaining system integrity, safety, and compliance.

📘 Table of Contents

- Introduction

- Why Leak Testing is Required

- Overview of NDT-LT Methods

- Industry Applications

- Applicable Standards and Regulations

- Challenges in Leak Testing

- Case Study Summary

- Emerging Technologies in LT

- Recommendations

- Conclusion

- References

1. 🧩 Introduction

Leak Testing (LT) is a vital subset of Non-Destructive Testing (NDT), used to detect leaks or verify leak-tightness in systems containing gases or liquids. It is widely used in sectors where failure could result in environmental harm, financial loss, or life-threatening hazards.

2. 📌 Why Leak Testing is Required

- Compliance with safety regulations (ASME, ISO, API, CE, IBR)

- Preventing contamination (e.g., in pharmaceuticals and food packaging)

- Avoiding economic loss from product loss or operational failure

- Maintaining system performance and reliability

- Environmental protection from hazardous emissions

3. 🛠 NDT-LT Methods Overview

| Method | Description | Sensitivity | Application |

|---|---|---|---|

| Bubble Testing | Uses soap solution to visualize leaks | 10⁻³ atm·cc/s | HVAC, piping |

| Pressure Drop/Vacuum Decay | Measures pressure change over time | 10⁻⁴ atm·cc/s | Sealed components |

| Helium Mass Spectrometer | Detects helium using a mass spec | 10⁻⁸ atm·cc/s | Aerospace, nuclear |

| Ultrasonic Testing | Listens to high-frequency sounds | 10⁻⁵ atm·cc/s | High-pressure systems |

| Tracer Gas (Halogen, Hydrogen) | Sniffers detect specific gases | 10⁻⁶ atm·cc/s | Refrigeration, auto |

| Vacuum Box Testing | Detects surface leaks on welds | Visual | Tank floors, shipbuilding |

4. 🏭 Industrial Applications

- Oil & Gas: Leak checks in pipelines, flanges, pressure vessels

- Pharma & Food: Packaging integrity for sterility

- Automotive: Leak testing of fuel tanks, brake lines

- Aerospace: Ensuring leak-free oxygen and fuel systems

- Power Generation: Leak proofing of condensers, turbines

- HVAC: Refrigerant leak testing for efficiency and compliance

5. 📚 Standards and Regulatory Framework

| Standard | Coverage |

|---|---|

| ASME Section V Article 10 | Leak testing in pressure vessels |

| ISO 20485 | General leak testing guidance |

| ASTM E498, E515 | Helium and vacuum testing |

| EN 1779 | Tracer gas leak detection |

| FDA, GMP, CE, PED | Industry-specific regulations |

6. ⚠️ Challenges in Leak Testing

- Micro leak detection in complex geometries

- Test sensitivity vs. practicality

- Environmental & safety concerns with tracer gases

- Operator skill and certification requirements

- Cost vs. benefit analysis for method selection

7. 📖 Case Study Summary

Industry: Oil & Gas

Issue: Undetected helium leak in a high-pressure exchanger

Method: Helium Mass Spectrometer Testing

Outcome: Early detection prevented hazardous failure and ensured timely commissioning.

8. 🚀 Emerging Trends & Technologies

- AI-powered leak analysis

- Automated ultrasonic drones

- Digital twin integration

- Laser-based leak sensors

- Portable helium detectors with real-time data logging

9. ✅ Recommendations

- Implement risk-based LT method selection

- Ensure training & certification under ASNT or ISO 9712

- Integrate leak testing in digital asset management systems

- Conduct periodic LT audits

- Align LT procedures with industry-specific best practices

10. 🧾 Conclusion

Leak Testing (NDT-LT) plays a non-negotiable role in safety, compliance, and efficiency across industries. As systems become more complex and regulations more stringent, organizations must adopt robust, standardized, and future-ready LT strategies to stay competitive and responsible.

📚 11. References

- ASME Boiler and Pressure Vessel Code, Section V

- ISO 20485:2018

- ASTM E498, E515, E1003

- FDA cGMP Guidelines

- EN 1779:1999

- API 650 / 653 Standards

Industrial Application of NDT-LT?

NDT-LT is used across industries wherever fluid or gas containment, pressure integrity, and leak-free operation are critical to safety, quality, compliance, or performance. Leak Testing ensures that no loss, contamination, or hazard occurs due to imperceptible leaks.

🔧 1. Oil & Gas Industry

| Application | Purpose |

|---|---|

| Pipelines (onshore/offshore) | Ensure no leakage of crude, gas, or chemicals |

| Pressure vessels and tanks | Prevent hazardous leaks and explosions |

| Flanges, valves, welds | Assure mechanical integrity and compliance with API standards |

| Gas compressors | Detect seal leaks under operating pressure |

🛠 Common Methods: Bubble Test, Pressure Drop, Ultrasonic Leak Detection, Helium Testing

✈️ 2. Aerospace & Aviation

| Application | Purpose |

|---|---|

| Fuel and hydraulic systems | Prevent fuel loss and avoid fire hazards |

| Oxygen delivery systems | Ensure safety for crew and passengers |

| Cabin pressurization systems | Maintain structural and passenger safety at high altitudes |

🛠 Common Methods: Helium Mass Spectrometer, Tracer Gas, Ultrasonic

🚗 3. Automotive Industry

| Application | Purpose |

|---|---|

| Fuel lines and tanks | Avoid fuel vapor leaks and meet emission norms |

| Radiators and cooling systems | Prevent engine overheating |

| Brake lines | Ensure system integrity and performance |

| Air-conditioning systems | Leak-proof refrigerant systems for efficiency and compliance |

🛠 Common Methods: Pressure Decay, Vacuum Decay, Tracer Gas (Hydrogen/Halogen)

⚡ 4. Power Generation (Thermal & Nuclear)

| Application | Purpose |

|---|---|

| Steam turbines and condensers | Avoid pressure loss, improve energy efficiency |

| Reactor coolant loops | Prevent radioactive leaks (nuclear) |

| Heat exchangers | Ensure integrity of tube-to-tube joints under high temperature |

🛠 Common Methods: Helium Leak Testing, Pressure Drop, Bubble Testing

💊 5. Pharmaceutical & Medical Devices

| Application | Purpose |

|---|---|

| Blister packs and sterile containers | Prevent contamination and spoilage |

| Injectable vials and syringes | Maintain sterility and dose accuracy |

| Medical devices (catheters, IV sets) | Ensure safety in internal usage |

🛠 Common Methods: Vacuum Decay, Mass Spectrometry, Micro-Flow Testing

🏭 6. Chemical and Petrochemical Plants

| Application | Purpose |

|---|---|

| Reactors, process vessels | Maintain process pressure and containment |

| Piping systems | Ensure no cross-contamination or leaks |

| Valve assemblies and instrumentation | Confirm operational reliability |

🛠 Common Methods: Ultrasonic, Helium Testing, Soap Solution, Pressure Hold Test

🌡️ 7. HVAC & Refrigeration

| Application | Purpose |

|---|---|

| AC and refrigeration coils | Ensure refrigerant containment (compliance with environmental laws) |

| Heat pumps and chillers | Improve system efficiency and safety |

| Ducting systems | Ensure leak-proof ventilation |

🛠 Common Methods: Halogen Leak Detector, Vacuum Decay, Pressure Rise Method

🚢 8. Shipbuilding and Marine

| Application | Purpose |

|---|---|

| Ballast tanks, fuel systems | Ensure water/gas tight integrity under harsh conditions |

| Engine rooms and piping | Detect and fix hazardous leaks in time |

| Watertight compartments | Maintain buoyancy and safety standards |

🛠 Common Methods: Vacuum Box Testing, Bubble Testing, Ultrasonic

🧪 9. Food & Beverage Packaging

| Application | Purpose |

|---|---|

| Vacuum-sealed packs | Prevent air ingress to avoid spoilage |

| Cans, bottles, pouches | Maintain hygiene and product shelf life |

| Modified Atmosphere Packaging (MAP) | Preserve freshness by maintaining internal gases |

🛠 Common Methods: Vacuum Decay, Bubble Emission Test, Pressure Rise

🧾 Summary Table

| Industry | Leak Testing Need | Typical Method |

|---|---|---|

| Oil & Gas | Safety, compliance | Ultrasonic, Helium |

| Aerospace | Critical systems | Helium Mass Spectrometer |

| Automotive | Emission control | Pressure Decay, Tracer Gas |

| Power | Efficiency, radiation safety | Vacuum, Helium |

| Pharma | Sterility | Vacuum Decay, Mass Spec |

| HVAC | Environmental safety | Halogen/Hydrogen Detection |

| Marine | Hull integrity | Vacuum Box, Soap |

| Food | Shelf life | Vacuum Decay |

References

- ^ Jump up to:a b c “Distribution, Transmission & Gathering, LNG, and Liquid Accident and Incident Data | PHMSA”. www.phmsa.dot.gov.

- ^ “Technology designed to detect U.S. energy pipeline leaks often fails”. Reuters. September 30, 2016 – via www.reuters.com.

- ^ Jump up to:a b c d e API RP 1130 (2007): Computational Pipeline Monitoring for Liquids. 1st Edition (September 2007). American Petroleum Institute.

- ^ TRFL (2003): Technische Regel für Fernleitungen (Technical Rule For Pipelines).

- ^ API 1155 (1995): Evaluation Methodology for Software Based Leak Detection Systems. 1st Edition (February 1995). American Petroleum Institute. Replaced by API RP 1130.

- ^ Jump up to:a b c d e f Geiger, G., Werner, T., Matko, D. (2003): Leak Detection and Locating – A Survey. 35th Annual PSIG Meeting, 15–17 October 2003, Bern, Switzerland.

- ^ Jump up to:a b c d e Geiger, G. (2008): Principles of Leak Detection. 1st Edition (September 2008). Krohne Oil & Gas, Breda (The Netherlands).

- ^ Avateq Corp. Press Release. New Leak Detection and Monitoring Technology Ensures Safety of Pipelines.

- ^ Benkherouf, A., & Allidina, A. Y. (1986). Leak Detection Methods for Gas Pipelines. IFAC Proceedings Volumes, 19(6), 205–210.

- ^ Torres, L., Verde, C., Besancon, G., & González, O. (2014). High‐gain observers for leak location in subterranean pipelines of liquefied petroleum gas. International Journal of Robust and Nonlinear Control, 24(6), 1127–1141.

- ^ Torres, L., Besançon, G., Navarro, A., Begovich, O., & Georges, D. (2011, March). Examples of pipeline monitoring with nonlinear observers and real-data validation. In 8th IEEE International Multi-Conf on Signals Systems and Devices, Sousse, Tunisia.

- ^ Torres, L. (2011). Modèles et observateurs pour les systèmes d’écoulement sous pression. Extension aux systèmes chaotiques (Doctoral dissertation, Grenoble).

- ^ Negrete, M. A., & Verde, C. (2012). Multi-leak reconstruction in pipelines by sliding mode observers. IFAC Proceedings Volumes, 45(20), 934–939.

- ^ Hauge, E., Aamo, O. M., & Godhavn, J. M. (2007). Model based pipeline monitoring with leak detection. IFAC Proceedings Volumes, 40(12), 318–323.

- ^ Berger, J.O. (1985): Statistical Decision Theory and Bayesian Analysis. Springer Series in Statistics. 2nd Edition (1985).

- ^ “Leak Rate Calculator | Discover Unknown Leak Test Values”. www.cincinnati-test.com.

- ^ Leak Detection and Locating – A Survey by Gerhard Geiger, University of Applied Sciences Gelsenkirchen, Faculty of Electrical Engineering “Archived copy” (PDF). Archived from the original (PDF) on 2015-11-29. Retrieved 2014-12-08.

- ^ CEPA (November 20, 2015). “The Inside Story on Pipeline Leak Detection”. Canadian Energy Pipeline Association. Retrieved March 21, 2017.

- ^ API (October 2009). “PPTS Operator Advisory: New Findings on Releases from Facilities Piping” (PDF). American Petroleum Institute. Retrieved March 21, 2017.

- ^ “New technology allows workers to control oil wells with their smartphones”. The Globe and Mail. Retrieved 2017-03-24.

- ^ TTK S.A.S. Liquid Hydrocarbon and Non-Conductive Solvent Sense Cable http://www.ttkuk.com/oil-leak-detection/products/sense-cable/hydrocarbon-sense-cables/fg-od/

- ^ Jackson, C.N.; Sherlock, C.N. (1998): Non-destructive Testing Handbook: Leak Testing, page 519, Library of Congress Cataloging-in-Publication Data, 2008.

- ^ Fuchs, H. V. (1991): Ten Year of Experience with Leak Detection by Acoustic Signal Analysis. Applied Acoustics 33 (1991), p. 1-19.

- ^ Johansen K, Kotopoulis S, Postema M (2015). “Ultrasonically driven antibubbles encapsulated by Newtonian fluids for active leakage detection”. Lecture Notes in Engineering and Computer Science. 2216: 750–754.

- ^ “Leakage detection and localization system – LEOS”.

- ^ “Technical Review of Leak Detection Technologies – Alaska Department of Environmental Conservation” (PDF). Archived from the original (PDF) on September 12, 2015.

- ^ Großwig, S. et al. (2001): Distributed Fiber Optical Temperature Sensing Technique – A Variable Tool for Monitoring Tasks. Proceedings of the 8th International Symposium on Temperature and Thermal Measurements in Industry and Science, June 19 – 21, 2001.

- “Mechanisms of the Hydrogen Leak Test”. www.fukuda-jp.com. Retrieved 2018-10-18.

- ^ “Leak Testing: Moving Beyond the Most Popular Methods – ReedLink Article”. Archived from the original on 2006-01-11. Retrieved 2006-08-06.

- ^ “DetecTape H2 – Low Cost Visual Hydrogen Leak Detector”. Detectape.com. Retrieved 2018-07-10.

- Cartz, Louis (1995). Nondestructive Testing. A S M International. ISBN 978-0-87170-517-4.

- ^ Charles Hellier (2003). Handbook of Nondestructive Evaluation. McGraw-Hill. p. 1.1. ISBN 978-0-07-028121-9.

- ^ “Introduction to Nondestructive Testing”. asnt.org.

- ^ Bridges, Andrew (November 2013). “High Speed Cameras for Non-Destructive Testing”. NASA TechBriefs. Retrieved 1 November 2013.

- ^ Blitz, Jack; G. Simpson (1991). Ultrasonic Methods of Non-Destructive Testing. Springer-Verlag New York, LLC. ISBN 978-0-412-60470-6.

- ^ Waldmann, T. (2014). “A Mechanical Aging Mechanism in Lithium-Ion Batteries”. Journal of the Electrochemical Society. 161 (10): A1742 – A1747. doi:10.1149/2.1001410jes.

- ^ “EDM Notch Reference Standards » PH Tool”. customers.phtool.com.

- ^ “Radiography (RT) Reference Standards » PH Tool”. customers.phtool.com.

- ^ “Connecticut Digital Archive | Connect. Preserve. Share”. collections.ctdigitalarchive.org. Retrieved 2019-08-18.

- ^ “Today in History – Fales & Gray Explosion Underscores Need for a Hartford Hospital | Connecticut History | a CTHumanities Project”. Retrieved 2019-08-17.

- ^ “History of PI”. www.ndt-ed.org. Archived from the original on 2009-08-23. Retrieved 2006-11-21.

- ^ Singh S, Goyal A (2007). “The origin of echocardiography: a tribute to Inge Edler”. Tex Heart Inst J. 34 (4): 431–8. PMC 2170493. PMID 18172524.

- ^ U.S. Patent 3,277,302, titled “X-Ray Apparatus Having Means for Supplying An Alternating Square Wave Voltage to the X-Ray Tube”, granted to Weighart on October 4, 1964, showing its patent application date as May 10, 1963 and at lines 1-6 of its column 4, also, noting James F. McNulty’s earlier filed co-pending application for an essential component of invention

- ^ U.S. Patent 3,289,000, titled “Means for Separately Controlling the Filament Current and Voltage on a X-Ray Tube”, granted to McNulty on November 29, 1966 and showing its patent application date as March 5, 1963

- ^ “ISO 9712:2012 Non-destructive testing — Qualification and certification of NDT personnel”.

- ^ Ahi, Kiarash (2018). “A Method and System for Enhancing the Resolution of Terahertz Imaging”. Measurement. 138: 614–619. Bibcode:2019Meas..138..614A. doi:10.1016/j.measurement.2018.06.044. S2CID 116418505.

- ^ ASTM E1351: “Standard Practice for Production and Evaluation of Field Metallographic Replicas” (2006)

- ^ BS ISO 3057 “Non-destructive testing – Metallographic replica techniques of surface examination” (1998)

- ^ “Fundamentals of Resonant Acoustic Method NDT” (2005)

- ^ “ICNDT Guide to Qualification and Certification of Personnel for NDT” (PDF). International Committee for NDT. 2012.

- ^ John Thompson (November 2006). Global review of qualification and certification of personnel for NDT and condition monitoring. 12th A-PCNDT 2006 – Asia-Pacific Conference on NDT. Auckland, New Zealand.

- ^ Recommended Practice No. SNT-TC-1A: Personnel Qualification and Certification in Nondestructive Testing, (2006)

- ^ ANSI/ASNT CP-189: ASNT Standard for Qualification and Certification of Nondestructive Testing Personnel, (2006)

- ^ Jump up to:a b c EN 4179: “Aerospace series. Qualification and approval of personnel for non-destructive testing” (2009)

- ^ AIA NAS410

- ^ Jump up to:a b ISO 9712: Non-destructive testing — Qualification and certification of NDT personnel (2012)

- ^ ANSI/ASNT CP-106: “ASNT Standard for Qualification and Certification of Nondestructive Testing Personnel” (2008)

- ^ “ASNT Central Certification Program”, ASNT Document ACCP-CP-1, Rev. 7 (2010)

- ^ EN 473: Non-destructive testing. Qualification and certification of NDT personnel. General principles, (2008)

- ^ Charles Hellier (2003). Handbook of Nondestructive Evaluation. McGraw-Hill. p. 1.25. ISBN 978-0-07-028121-9.

- ^ Charles Hellier (2003). Handbook of Nondestructive Evaluation. McGraw-Hill. p. 1.26. ISBN 978-0-07-028121-9.

- ^ Directive 97/23/EC of the European Parliament and of the Council of 29 May 1997 on the approximation of the laws of the Member States concerning pressure equipment, Annex I, paragraph 3.1.3

- ^ EFNDT/SEC/P/05-006: Agreement for EFNDT multilateral recognition of NDT personnel certification schemes (2005)

- ^ http://www.nrcan-rncan.gc.ca/smm-mms/ndt-end/index-eng.htm : The NDT Certifying Agency (CANMET-MTL)

- ^ The relevant national standard for Canada is CAN/CGSB-48.9712-2006 “Qualification and Certification of Non-Destructive Testing Personnel.”, which complies with the requirements of ISO 9712:2005 and EN 473:2000.

- ^ Charles Hellier (2003). Handbook of Nondestructive Evaluation. McGraw-Hill. p. 1.27. ISBN 978-0-07-028121-9.

- ^ R. Marini and P. Ranos: “Current Issues in Qualification and Certification of Non-Destructive Testing Personnel in the Aerospace Industry“, ECNDT 2006 – Th.3.6.5

- ^ AIA-NAS-410: “Aerospace Industries Association, National Aerospace Standard, NAS Certification and Qualification of Nondestructive Test Personnel”

- ^ Jump up to:a b ASTM E-1316: “Standard Terminology for Nondestructive Examinations”, The American Society for Testing and Materials, in Volume 03.03 NDT, 1997

- ^ T. Oldberg and R. Christensen (1999). “Erratic Measure”. 4 (5). NDT.net.

{{cite journal}}: Cite journal requires|journal=(help) - ^ T. Oldberg (2005). “An Ethical Problem in the Statistics of Defect Detection Test Reliability”. 10 (5). NDT.net.

{{cite journal}}: Cite journal requires|journal=(help).