What is Required Calibration?

🎯 Why is Calibration Required?

- ✅ Accuracy Assurance – Instruments drift over time; calibration restores correct measurements.

- ✅ Regulatory Compliance – Required by standards like ISO 9001, ISO/IEC 17025, FDA, etc.

- ✅ Safety – Ensures equipment like pressure gauges, thermometers, and balances operate safely.

- ✅ Quality Control – Prevents product defects due to measurement errors.

- ✅ Traceability – Links measurements to national or international standards.

📅 When is Calibration Required?

| Condition | Description |

|---|---|

| 📌 Before First Use | To verify factory settings meet accuracy requirements. |

| 📌 At Regular Intervals | Based on manufacturer’s recommendation or industry standard (e.g., annually). |

| 📌 After Repairs | To ensure the equipment still performs correctly after maintenance. |

| 📌 If Dropped/Damaged | Even slight physical damage may affect accuracy. |

| 📌 After Environmental Changes | Sudden shifts in temperature, humidity, or pressure can affect measurement tools. |

🧪 What Needs Required Calibration?

- Balances & Scales

- Temperature Sensors & Thermometers

- Pressure Gauges

- Flow Meters

- Electrical Test Equipment

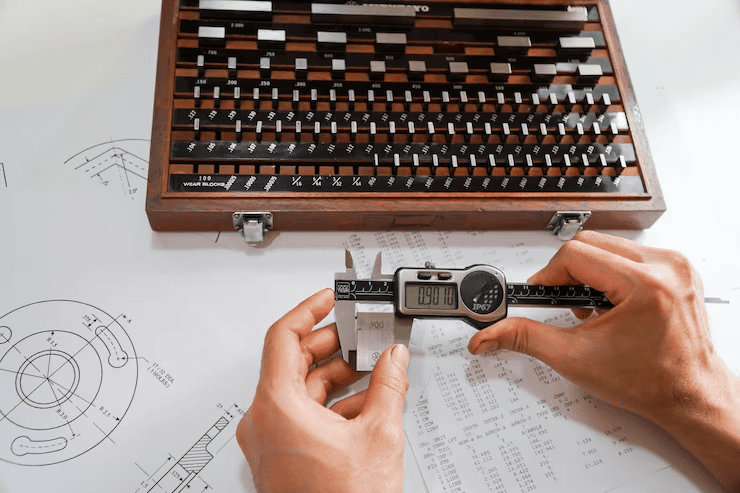

- Dimensional Tools (Calipers, Micrometers)

- Laboratory Instruments

- Medical Devices

📜 Documentation in Required Calibration

A proper calibration process must include:

- Calibration Certificate

- Traceability to national/international standards

- Measurement Uncertainty

- Before & After Readings

- Calibration Date and Due Date

⚠️ Consequences of Skipping Required Calibration

- Inaccurate Measurements

- Product Recalls or Failures

- Non-compliance with ISO/FDA/GMP

- Safety Hazards

- Reputation Damage

Who is Required Calibration?

🧑🔧 1. Industries and Professionals That Require Calibration

📌 Industries

Calibration is required in any industry where measurement accuracy is critical:

| Industry | Why Calibration is Required |

|---|---|

| 🏭 Manufacturing | Ensures product quality, tolerances, and safety. |

| 🧪 Laboratories (QA/QC) | Maintains test accuracy and certification standards. |

| 🏥 Healthcare & Medical | Calibrates diagnostic and therapeutic devices. |

| 🛫 Aerospace & Defense | Critical for safety, performance, and compliance. |

| ⚗️ Pharmaceuticals | Mandatory for GMP compliance and drug safety. |

| 🔬 Food & Beverages | Ensures hygiene, temperature control, and regulatory compliance. |

| ⚡ Electrical/Power Sector | Ensures voltage, current, and resistance measurements are precise. |

| 🌍 Environmental Monitoring | Calibrates sensors for pollution, air, and water quality. |

👨💼 2. Roles Responsible for Calibration

| Role/Person | Responsibility |

|---|---|

| 🧑🔬 Quality Manager | Oversees compliance with ISO, FDA, or regulatory standards. |

| 🔧 Calibration Technician | Performs actual calibration using traceable standards. |

| 🧑🏭 Production Engineer | Ensures machines and tools stay within operating limits. |

| 🧾 Audit/Compliance Officer | Verifies calibration records during audits. |

| 🧑🔬 Lab Analyst | Uses calibrated instruments for test accuracy. |

| 🧰 Maintenance Team | Schedules calibration with service providers. |

🏢 3. Organizations Required to Conduct Calibration

- ISO 9001 / ISO 17025 certified organizations

- FDA-regulated manufacturers

- NABL-accredited laboratories

- BIS/ISI certified companies

- Companies following Good Manufacturing Practices (GMP)

📜 Summary Answer

“Who is required calibration?” —

Any organization, industry, or professional relying on measurement equipment for quality, safety, compliance, or scientific accuracy must ensure calibration is performed regularly and traceably.

When is Required Calibration?

📅 Calibration is Required in These Key Situations:

| 🔍 Condition | 📝 Why Calibration is Needed |

|---|---|

| 🆕 Before First Use | To ensure the instrument meets accuracy standards from the start. |

| 📆 At Regular Intervals | Based on industry standards, manufacturer guidelines, or internal SOPs (e.g., every 6 months or annually). |

| 🔧 After Repairs or Maintenance | To verify accuracy hasn’t been affected by part replacement or repair. |

| 💥 After an Incident (Drop, Shock, Overload) | Even minor physical damage can affect internal components and measurement accuracy. |

| 🌡️ After Environmental Changes | Significant changes in temperature, humidity, or pressure may affect sensitive equipment. |

| 🧪 Before Critical Measurements or Projects | Especially for regulatory or high-risk work where errors are unacceptable. |

| ⚠️ If Results Are Inconsistent | If instruments give abnormal or inconsistent readings during routine use. |

| 📋 As Per Quality or Regulatory Audits | Calibration may be requested or required before or during external/internal audits. |

⏰ Common Calibration Frequency Guidelines

| Equipment Type | Recommended Interval |

|---|---|

| Analytical Balances | Every 3–6 months |

| Temperature Sensors (Thermocouples, RTDs) | Every 6–12 months |

| Pressure Gauges | Annually |

| Multimeters, Oscilloscopes | 1 year |

| Laboratory Instruments (pH meters, spectrophotometers) | 6–12 months |

| Medical Devices | As per hospital/clinic SOP, often every 6 months |

🧠 Note: The frequency may be increased based on:

- Manufacturer’s recommendation

- Equipment criticality

- Frequency of use

- Environmental conditions

- Past calibration history

🛑 What Happens If You Miss Required Calibration?

- Measurement errors

- Non-compliance with ISO, FDA, or NABL

- Product recalls or process failures

- Legal liability

- Failed audits

📌 Summary Answer:

Calibration is required:

- Before first use

- On a fixed schedule (e.g., every 6–12 months)

- After incidents or repairs

- When accuracy is critical

- Or when inconsistent results appear.

Where is Required Calibration?

📍 1. In Industries and Facilities Using Measurement Instruments

| 🏭 Industry | 📍 Where Calibration is Required |

|---|---|

| ⚙️ Manufacturing Plants | On production lines, testing benches, QC labs |

| 🧪 Testing & Calibration Labs | Everywhere instruments are used—especially NABL/ISO 17025 certified labs |

| 🏥 Hospitals & Clinics | ICU, pathology labs, radiology, operating rooms |

| ⚗️ Pharmaceutical & Biotech Plants | Clean rooms, QA/QC labs, process control areas |

| 🛠️ Tool Rooms & Machine Shops | Measuring stations, CNC machines, inspection departments |

| 🛫 Aerospace & Defense Facilities | R&D labs, avionics, flight testing setups |

| 🌿 Environmental Monitoring Stations | Field data points, weather stations, mobile vans |

| 🚢 Marine and Oil & Gas Platforms | Offshore calibration for pressure, flow, temperature equipment |

| ⚡ Power & Energy Plants | Control rooms, switchyards, field equipment zones |

🧰 2. In Specific Locations Within an Organization

| 🧩 Location | 📋 Examples |

|---|---|

| 🧪 Laboratories | Calibrate balances, pipettes, pH meters, spectrophotometers. |

| 📐 Inspection/QA Rooms | Dimensional tools (vernier, micrometer), hardness testers. |

| 🏭 Production Floor | Machines using sensors for temperature, flow, pressure. |

| 🔬 Metrology Room | Master instruments and gauges are calibrated here. |

| 🚛 On-Site (Field Calibration) | For heavy machinery, pipelines, weather stations, etc. |

| 📦 Incoming Material QC | Weighing scales, test benches for raw material inspection. |

🌍 3. By Location of Service

| Type | Description |

|---|---|

| 🧪 In-House Calibration | Performed within the facility by internal technicians using reference standards. |

| 🚚 On-Site Calibration | External technicians calibrate equipment at the user’s location (e.g., large or fixed equipment). |

| 🧳 Off-Site Calibration (at Accredited Labs) | Instruments are sent to specialized NABL/ISO 17025 labs for high-precision calibration. |

📜 Where Calibration is Mandated (Compliance)

- ISO 9001 / 17025 labs: Wherever instruments impact product/process quality.

- FDA/GMP environments: Any critical instrument used in production or testing.

- BIS, NABL-accredited, or Metrology facilities: For traceable, certified calibration.

📌 Summary Answer:

Required calibration takes place wherever precision measurement tools are used — in factories, laboratories, medical facilities, field stations, and QA environments. It may occur on-site, off-site, or in dedicated calibration labs, depending on the equipment and compliance needs.

How is Required Calibration?

🧪 Step-by-Step: How Required Calibration is Done

| 🔢 Step | 🔍 Description |

|---|---|

| 1️⃣ Preparation | Identify equipment, check calibration history, clean the device, and ensure it’s in stable condition. |

| 2️⃣ Reference Standard Selection | Use a traceable standard (to national/international standards like NIST, NABL, ISO) with higher accuracy than the instrument being tested. |

| 3️⃣ Environmental Control | Perform calibration under controlled conditions (temperature, humidity) as per standard requirements. |

| 4️⃣ Baseline Measurement (“As Found”) | Measure the instrument’s current performance before any adjustments to record deviations. |

| 5️⃣ Adjustment (if needed) | If the instrument is out of tolerance, adjust it to bring it within allowable limits. |

| 6️⃣ Verification (“As Left”) | Remeasure to confirm the instrument is now within accuracy limits. |

| 7️⃣ Documentation | Record all data, including readings, standards used, uncertainty, and calibration results. |

| 8️⃣ Labeling | Apply a calibration sticker/tag with date, due date, and certificate reference. |

| 9️⃣ Issuing Certificate | A calibration certificate is issued containing: |

| – Equipment details | |

| – Calibration date and due date | |

| – Technician name | |

| – Traceability statement | |

| – Measurement uncertainty |

🧰 Methods of Required Calibration

| Method | Used For | Example |

|---|---|---|

| 🧪 Comparison Method | Comparing against a known standard | Calibrating a thermometer using a reference temperature bath |

| 📈 Graphical or Regression Method | Generating correction curves | Flow meter calibration across different flow rates |

| ⚖️ Substitution Method | Switching known loads or values | Weighing scale calibration using certified weights |

| 🔁 Zero and Span Calibration | Adjusting minimum and maximum readings | Pressure gauge with 0–100 psi range |

| 🧑🔬 Automated Calibration | Using software and calibrators | Digital multimeter or oscilloscope calibration |

🏷️ Types of Calibration Records

- Calibration Certificate

- Calibration Log Sheet

- Instrument History Card

- Traceability Chain

- Uncertainty Budget

📜 Compliance Standards Followed

- ✅ ISO/IEC 17025 (Testing & Calibration Labs)

- ✅ ISO 9001 (Quality Management)

- ✅ FDA, GMP, GLP

- ✅ NIST/NABL traceability standards

📌 Summary Answer:

Required calibration is done by comparing a device’s performance against a known, traceable standard, recording the deviations, making necessary adjustments, verifying the results, and documenting the process as per ISO/NABL/industry standards. It involves precision, procedure, and proof.

Case Study on Calibration?

Ensuring Product Quality through Regular Calibration in a Pharmaceutical Manufacturing Plant

🎯 Objective:

To demonstrate how scheduled calibration of laboratory and production equipment helped a pharmaceutical company reduce product recalls and achieve GMP compliance.

🏢 Company Overview:

- Name: BioCure Pharmaceuticals Pvt. Ltd.

- Industry: Pharmaceutical manufacturing

- Location: Maharashtra, India

- Certifications: WHO-GMP, ISO 9001, FDA

📍 Situation Before Calibration Compliance:

Problems Faced:

- Increased batch rejection due to variability in drug content.

- Inconsistent pH and viscosity measurements from QC labs.

- Audit nonconformities raised by external GMP inspectors.

- No clear schedule or traceability in calibration records.

Instruments Used (Uncalibrated/Overdue):

- Analytical balances

- pH meters

- Viscometers

- Temperature & humidity chambers

- UV-Vis spectrophotometer

🔬 Action Taken – Implementation of a Calibration Program:

| Step | Description |

|---|---|

| 🧩 Audit and Inventory | A complete audit was done to list all critical instruments. |

| 📅 Calibration Schedule Created | Equipment categorized as per criticality (monthly, quarterly, annually). |

| 🧪 Calibration Performed | All devices calibrated by a NABL-accredited third-party lab. In-house tools cross-verified. |

| 📋 SOP Documentation | Calibration SOPs were written, validated, and implemented in the QMS. |

| 🏷️ Calibration Labeling and Logbook | Each instrument labeled with ID, due date, and next calibration date. Records digitized. |

📊 Results After 6 Months:

| Metric | Before Calibration | After Calibration Program |

|---|---|---|

| ❌ Batch Rejection Rate | 12% | 2% |

| ❌ GMP Audit Observations | 6 major | 0 major |

| ✅ Equipment Accuracy Failures | 18 cases/month | < 2 cases/month |

| 📈 Product Consistency (Assay Values) | ±7% variation | Within ±2% variation |

| 🕒 Downtime Due to Measurement Error | 48 hours/month | 6 hours/month |

💡 Key Takeaways:

- Calibration is not just a compliance need; it’s a quality driver.

- Regular calibration minimized process variability, ensured regulatory compliance, and restored customer confidence.

- Investment in SOPs, trained staff, and third-party calibration labs paid off in reduced costs and increased efficiency.

📜 Conclusion:

Calibration played a transformative role in improving product reliability and operational excellence. The case of BioCure Pharmaceuticals illustrates that systematic, traceable, and scheduled calibration is essential for any regulated industry aiming for quality and trust.

White paper on Calibration?

The Strategic Importance of Calibration in Quality and Compliance Systems

🔍 Executive Summary

Calibration is the cornerstone of quality assurance and compliance in industries reliant on precise measurement. This white paper explores the importance, methodologies, regulatory implications, and future direction of calibration in regulated and high-precision environments. It provides guidance on implementing an effective calibration system that supports traceability, operational excellence, and competitive advantage.

📘 Table of Contents

- Introduction

- What Is Calibration?

- Why Calibration Is Required

- When and Where Calibration Is Needed

- How Calibration Is Performed

- Standards and Regulatory Compliance

- Risks of Skipping Calibration

- Technological Advancements in Calibration

- Case Study Snapshot

- Recommendations

- Conclusion

1️⃣ Introduction

In modern industries—from aerospace and pharmaceuticals to electronics and food safety—measurement accuracy directly impacts safety, quality, and reputation. Calibration ensures that instruments provide measurements within specified tolerances, offering confidence in processes, decisions, and products.

2️⃣ What Is Calibration?

Calibration is the documented comparison of a measurement device to a traceable reference standard.

It involves:

- Measuring instrument output

- Comparing with known values

- Adjusting if necessary

- Recording and certifying the result

3️⃣ Why Calibration Is Required

- 🔹 Assures Measurement Accuracy

- 🔹 Enables Traceability to International Standards

- 🔹 Reduces Risk of Product Non-Conformance

- 🔹 Supports Quality Systems (ISO, FDA, GMP)

- 🔹 Enhances Customer Trust and Brand Reputation

4️⃣ When and Where Calibration Is Needed

📅 When:

- Before first use

- Periodically (e.g., every 6–12 months)

- After impact, repair, or exposure to extreme conditions

- Before critical production runs

📍 Where:

- Production floors

- Quality control laboratories

- Testing facilities

- Environmental monitoring stations

- On-site or off-site calibration labs

5️⃣ How Calibration Is Performed

Calibration follows a structured process:

- Equipment preparation and environmental control

- Use of traceable reference standards

- “As Found” reading recording

- Adjustment (if necessary)

- “As Left” verification

- Documentation: calibration certificate, uncertainty, traceability chain

6️⃣ Standards and Regulatory Compliance

Compliance requires adherence to:

| Standard | Purpose |

|---|---|

| ISO/IEC 17025 | Competence of testing and calibration labs |

| ISO 9001 | Quality management calibration requirements |

| FDA/GMP | Mandatory calibration for medical, pharma, food |

| NABL/NIST | Traceable standards and accreditation bodies |

7️⃣ Risks of Skipping Calibration

- ❌ Production delays

- ❌ Safety hazards

- ❌ Failed audits and legal penalties

- ❌ Loss of ISO/FDA certification

- ❌ Reduced equipment life and increased breakdowns

8️⃣ Technological Advancements

- 📡 Remote Calibration & IoT Monitoring

- 🤖 Automated Calibration Systems (ACS)

- 📱 Digital Calibration Certificates (DCC)

- 📊 Calibration Management Software (CMS)

These technologies increase reliability, efficiency, and audit readiness.

9️⃣ Case Study Snapshot

Company: BioCure Pharmaceuticals

Issue: 12% batch rejection due to poor instrument control

Solution: Annual calibration with third-party NABL labs

Result: 83% reduction in deviations, zero major audit findings

(Full case study available on request.)

🔟 Recommendations

- Develop a calibration master list

- Use traceable standards and certified labs

- Implement automated reminders and logs

- Include calibration in internal audits and training

- Continuously review uncertainty budgets

🔚 Conclusion

Calibration is not a cost—it’s an investment in reliability, safety, and success.

A structured calibration program builds a foundation for process control, regulatory compliance, and customer satisfaction across industries. Organizations must treat calibration as a strategic quality enabler in today’s competitive landscape.

Industrial Application of Calibration?

Calibration is a core function in every industry that depends on precision measurement for safety, compliance, and performance. Its applications range from quality control in manufacturing to real-time monitoring in energy and aerospace sectors.

🔧 1. Manufacturing & Engineering Industry

🛠️ Applications:

- Calibration of micrometers, calipers, pressure gauges, and torque wrenches.

- Machine tool accuracy for CNC operations.

- Inspection and quality assurance of parts.

✅ Benefits:

- Ensures dimensional accuracy.

- Reduces scrap and rework.

- Supports ISO 9001 compliance.

⚗️ 2. Pharmaceutical & Biotech Industry

🧪 Applications:

- Balances, pH meters, HPLC, UV-Vis spectrometers.

- Incubators, autoclaves, cleanroom environment monitors.

✅ Benefits:

- Compliance with GMP, FDA, WHO.

- Reduces batch failures.

- Guarantees patient safety through drug accuracy.

🩺 3. Healthcare & Medical Device Industry

🩻 Applications:

- Calibration of thermometers, ventilators, infusion pumps, blood pressure monitors.

- Diagnostic imaging equipment (X-ray, CT, MRI).

✅ Benefits:

- Prevents diagnostic errors.

- Ensures life-saving devices function reliably.

- Required by NABH, FDA, and CE certifications.

✈️ 4. Aerospace & Defense Industry

🛫 Applications:

- Avionics instruments (altimeters, gyroscopes, radar systems).

- Force sensors, accelerometers, and simulation equipment.

✅ Benefits:

- Ensures flight safety and mission-critical accuracy.

- Supports AS9100 and MIL-STD standards.

⚡ 5. Power & Energy Sector

🔋 Applications:

- Voltage/current calibrators, protection relays, transformer testing.

- SCADA systems and environmental monitors.

✅ Benefits:

- Prevents electrical failures.

- Ensures grid stability.

- Compliance with CEA, ISO, and BIS standards.

🛢️ 6. Oil & Gas / Petrochemical Industry

🛢️ Applications:

- Flow meters, level sensors, pressure transmitters.

- Process control analyzers in hazardous environments.

✅ Benefits:

- Prevents leakage, explosion, or overpressure events.

- Maintains process integrity.

- Meets API, IECEx, and ISO 17025 compliance.

🚛 7. Automotive Industry

🚗 Applications:

- Torque tools, emission testers, fuel injection test benches.

- Dimensional metrology for parts.

✅ Benefits:

- Enhances performance, efficiency, and safety.

- Required for IATF 16949 certification.

🏗️ 8. Construction & Civil Engineering

🧱 Applications:

- Surveying equipment (total stations, laser levels).

- Concrete and soil testing equipment.

✅ Benefits:

- Ensures structural integrity.

- Enables accurate mapping and compliance with ASTM standards.

🌍 9. Environmental Monitoring

🌿 Applications:

- Weather stations, air quality monitors, water testing meters.

- Calibration of gas analyzers and flow samplers.

✅ Benefits:

- Supports sustainable operations.

- Ensures accurate environmental impact reports.

- Compliance with EPA, CPCB, ISO 14001.

🏭 10. Food & Beverage Industry

🥫 Applications:

- Calibration of temperature sensors in cold chains.

- Weighing systems, pH meters, metal detectors.

✅ Benefits:

- Maintains food safety (HACCP compliance).

- Prevents contamination and spoilage.

- Required by FSSAI, ISO 22000.

📌 Summary Table: Calibration Across Industries

| Industry | Key Instruments | Standard Compliance |

|---|---|---|

| Pharma | Balances, HPLC, Incubators | GMP, FDA, WHO |

| Aerospace | Sensors, Avionics, Pressure Meters | AS9100, MIL-STD |

| Power | Relays, SCADA, Voltmeters | CEA, BIS |

| Medical | Thermometers, BP monitors | NABH, CE |

| Automotive | Torque wrenches, Emission tools | IATF 16949 |

| Food | pH meters, temp loggers | FSSAI, ISO 22000 |

🧠 Final Thoughts:

Calibration is not just technical—it’s strategic.

It protects product quality, safety, legal compliance, and customer trust. Every instrument used to make critical decisions must be calibrated regularly, documented properly, and traceable to national or international standards.

Reference

- ^ JCGM 200:2008 International vocabulary of metrology Archived 2019-10-31 at the Wayback Machine — Basic and general concepts and associated terms (VIM)

- ^ Jump up to:a b ISO 9001: “Quality management systems — Requirements” (2008), section 7.6.

- ^ Jump up to:a b ISO 17025: “General requirements for the competence of testing and calibration laboratories” (2005), section 5.

- ^ Faison, C. Douglas; Brickenkamp, Carroll S. (March 2004). “Calibration Laboratories: Technical Guide for Mechanical Measurements” (PDF). NIST Handbook 150-2G. NIST. Archived from the original (PDF) on 12 May 2015. Retrieved 14 June 2015.

- ^ “Metrology, Pressure, Thermal & Eletrotechnical Measurement and Calibration”. Fluid Control Research Institute (FCRI), Ministry of Heavy Industries & Public Enterprises, Govt. of India. Archived from the original on 14 June 2015. Retrieved 14 June 2015.

- ^ Haider, Syed Imtiaz; Asif, Syed Erfan (16 February 2011). Quality Control Training Manual: Comprehensive Training Guide for API, Finished Pharmaceutical and Biotechnologies Laboratories. CRC Press. p. 49. ISBN 978-1-4398-4994-1.

- ^ Bare, Allen (2006). Simplified Calibration Interval Analysis (PDF). Aiken, SC: NCSL International Workshop and Symposium, under contract with the Office of Scientific and Technical Information, U.S. Department of Energy. pp. 1–2. Archived (PDF) from the original on 2007-04-18. Retrieved 28 November 2014.

- ^ “ANSI/NCSL Z540.3-2006 (R2013)”. The National Conference of Standards Laboratories (NCSL) International. Archived from the original on 2014-11-20. Retrieved 28 November 2014.

- ^ “Calibration Systems Requirements (Military Standard)” (PDF). Washington, DC: U.S. Department of Defense. 1 August 1998. Archived from the original (PDF) on 2005-10-30. Retrieved 28 November 2014.

- ^ Jump up to:a b Ligowski, M.; Jabłoński, Ryszard; Tabe, M. (2011), Jabłoński, Ryszard; Březina, Tomaš (eds.), Procedure for Calibrating Kelvin Probe Force Microscope, Mechatronics: Recent Technological and Scientific Advances, p. 227, doi:10.1007/978-3-642-23244-2, ISBN 978-3-642-23244-2, LCCN 2011935381

- ^ Military Handbook: Evaluation of Contractor’s Calibration System (PDF). U.S. Department of Defense. 17 August 1984. p. 7. Archived (PDF) from the original on 2014-12-04. Retrieved 28 November 2014.

- ^ Procedure for calibrating pressure gauges (USBR 1040) (PDF). U.S. Department of the Interior, Bureau of Reclamation. pp. 70–73. Archived (PDF) from the original on 2013-05-12. Retrieved 28 November 2014.

- ^ “KNC Model 3666 Automatic Pressure Calibration System” (PDF). King Nutronics Corporation. Archived from the original (PDF) on 2014-12-04. Retrieved 28 November 2014.

- ^ “the definition of calibrate”. Dictionary.com. Retrieved 18 March 2018.

- ^ Baber, Zaheer (1996). The Science of Empire: Scientific Knowledge, Civilization, and Colonial Rule in India. SUNY Press. pp. 23–24. ISBN 978-0-7914-2919-8.

- ^ Franceschini, Fiorenzo; Galetto, Maurizio; Maisano, Domenico; Mastrogiacomo, Luca; Pralio, Barbara (6 June 2011). Distributed Large-Scale Dimensional Metrology: New Insights. Springer Science & Business Media. pp. 117–118. ISBN 978-0-85729-543-9.

- ^ Ackroyd, Peter (16 October 2012). Foundation: The History of England from Its Earliest Beginnings to the Tudors. St. Martin’s Press. pp. 133–134. ISBN 978-1-250-01367-5.

- ^ Bland, Alfred Edward; Tawney, Richard Henry (1919). English Economic History: Select Documents. Macmillan Company. pp. 154–155.

- ^ Tilford, Charles R (1992). “Pressure and vacuum measurements” (PDF). Physical Methods of Chemistry: 106–173. Archived from the original (PDF) on 2014-12-05. Retrieved 28 November 2014.

- ^ Fridman, A. E.; Sabak, Andrew; Makinen, Paul (23 November 2011). The Quality of Measurements: A Metrological Reference. Springer Science & Business Media. pp. 10–11. ISBN 978-1-4614-1478-0.

- ^ Cuscó, Laurence (1998). Guide to the Measurement of Pressure and Vacuum. London: The Institute of Measurement and Control. p. 5. ISBN 0-904457-29-X.

- Nubiola, Albert; Bonev, Ilian A. (2013-02-01). “Absolute calibration of an ABB IRB 1600 robot using a laser tracker”. Robotics and Computer-Integrated Manufacturing. 29 (1): 236–245. doi:10.1016/j.rcim.2012.06.004.

- ^ Nof, Shimon Y (1999). Handbook of industrial robotics (Vol 1 ed.). Wiley and Sons. pp. 72–74.

- ^ Lightcap, C.; Banks, S. (2007-10-01). “Dynamic identification of a mitsubishi pa10-6ce robot using motion capture”. 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems. pp. 3860–3865. doi:10.1109/IROS.2007.4399425. ISBN 978-1-4244-0911-2. S2CID 14339917.

- ^ “ISO 9283:1998 – Manipulating industrial robots — Performance criteria and related test methods”. ISO. Retrieved 2017-01-03.

- ^ “Helmut Schmidt University”.

- ^ “Parallel Kinematics Calibration Without Parameter Identification”. Scribd. Retrieved 2017-01-03.

- ^ RoboDK. “Robot calibration – RoboDK”. www.robodk.com. Retrieved 2017-01-03.

- Taylor (1987), p. 133.

- ^ Jump up to:a b c Aitken (1990), p. 66–67.

- ^ Enk, J.; Devault, A.; Debruyne, R.; King, C. E.; Treangen, T.; O’Rourke, D.; Salzberg, S. L. l; Fisher, D.; MacPhee, R.; Poinar, H. (2011). “Complete Columbian mammoth mitogenome suggests interbreeding with woolly mammoths”. Genome Biology. 12 (5): R51. doi:10.1186/gb-2011-12-5-r51. PMC 3219973. PMID 21627792.

- ^ P. Semal; A. Hauzeur; H. Rougier; I. Crevecoeur; M. Germonpré; S. Pirson; P. Haesaerts; C. Jungels; D. Flas; M. Toussaint; B. Maureille; H. Bocherens; T. Higham; J. van der Pflicht (2013). “Radiocarbon dating of human remains and associated archaeological material”. Anthropologica et Præhistorica. 123/2012: 331–356.

- ^ Jump up to:a b Reimer, Paula J.; et al. (2013). “IntCal13 and Marine13 radiocarbon age calibration curves 0–50,000 years cal BP”. Radiocarbon. 55 (4): 1869–1887. doi:10.2458/azu_js_rc.55.16947. hdl:10289/8955.

- ^ Heaton, Timothy J.; Blaauw, Maarten; Blackwell, Paul G.; Ramsey, Christopher Bronk; Reimer, Paula J.; Scott, E. Marian (August 2020). “The IntCal20 Approach to Radiocarbon Calibration Curve Construction: A New Methodology Using Bayesian Splines and Errors-in-Variables”. Radiocarbon. 62 (4): 821–863. doi:10.1017/RDC.2020.46. ISSN 0033-8222.

- ^ Taylor (1987), pp. 19–21.

- ^ Jump up to:a b Bowman (1995), pp. 16–20.

- ^ Jump up to:a b Suess (1970), p. 303.

- ^ Jump up to:a b c d Bowman (1995), pp. 43–49.

- ^ Reimer, Paula J (2020). “The IntCal20 Northern Hemisphere Radiocarbon Age Calibration Curve (0–55 cal kBP)”. Radiocarbon. 62 (4): 725–757. doi:10.1017/RDC.2020.41. hdl:11585/770531.

- ^ Stuiver, M.; Braziunas, T.F. (1993). “Modelling atmospheric 14

C influences and 14

C ages of marine samples to 10,000 BC”. Radiocarbon. 35 (1): 137–189. doi:10.1017/S0033822200013874. - ^ Heaton, Timothy J.; Köhler, Peter; Butzin, Martin; Bard, Edouard; Reimer, Ron W.; Austin, William E. N.; Ramsey, Christopher Bronk; Grootes, Pieter M.; Hughen, Konrad A.; Kromer, Bernd; Reimer, Paula J.; Adkins, Jess; Burke, Andrea; Cook, Mea S.; Olsen, Jesper (2020). “Marine20—The Marine Radiocarbon Age Calibration Curve (0–55,000 cal BP)”. Radiocarbon. 62 (4): 779–820. doi:10.1017/RDC.2020.68. hdl:1912/26513. ISSN 0033-8222.

- ^ “Discussion: Reporting and Calibration of Post-Bomb 14C Data”. Radiocarbon. 46 (3): 1299–1304. 2004. doi:10.1017/S0033822200033154. ISSN 0033-8222.

- ^ “OxCal”. Oxford Radiocarbon Accelerator Unit. Oxford University. 23 May 2014. Retrieved 26 June 2014.

- ^ Jump up to:a b Stuiver, M.; Reimer, P.J. Reimer; Reimer, R. (2013). “CALIB Radiocarbon Calibration”. CALIB 14C Calibration Program. Queen’s University, Belfast. Retrieved 26 June 2014.

- ^ Jump up to:a b Aitken (1990), p. 101.

- ^ Jump up to:a b Walker (2005), pp. 35−37.

- ^ Aitken (1990), pp. 103−105.

- ^ Walker (2005), pp. 207−209.

- ^ Gillespie (1986), pp. 30−32.

- M. Teillet, P. (1986). Image correction for radiometric effects in remote sensing. International Journal of Remote Sensing – INT J REMOTE SENS. 7. 1637-1651. 10.1080/01431168608948958.

- ^ H. Kim, Hongsuk & C. Elman, Gregory. (1990). Normalization of satellite imagery. International Journal of Remote Sensing. 11. 10.1080/01431169008955098.

- ^ D. Hall; G. Riggs; V. Salomonson. (1995). “Development of methods for mapping global snow cover using moderate resolution imaging spectroradiometer data.” Remote Sensing of Environment. 54, no. 2: 127-140.

- ^ A. Moghimi, T. Celik, A. Mohammadzadeh and H. Kusetogullari, “Comparison of Keypoint Detectors and Descriptors for Relative Radiometric Normalization of Bitemporal Remote Sensing Images,” in IEEE Journal of Selected Topics in Applied Earth Observations and Remote Sensing, vol. 14, pp. 4063-4073, 2021, doi: 10.1109/JSTARS.2021.3069919.

- ^ Yang, Xiajun, and C. P. Lo. “Relative radiometric normalization performance for change detection from multi-date satellite images.” Photogrammetric Engineering and Remote Sensing 66.8 (2000): 967-980.